Manufacturer, Supplier & Exporter of

a wide range of Dyes, Pigments & Food Colours

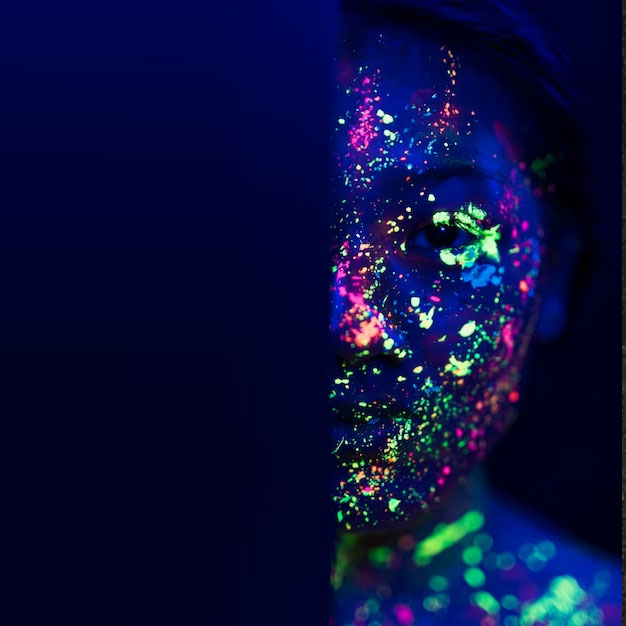

Fluorescent Pigments

Fluorescent pigments are a type of colouring agent that have the unique property of emitting light when exposed to ultraviolet (UV) radiation. These pigments are widely used in various industrial applications due to their vivid and vibrant colours, high colour strength, and excellent light fastness properties.

One of the key properties of fluorescent pigments is their ability to absorb UV light and then re-emit it as visible light, which makes them highly visible even in low-light conditions. These pigments are available in a range of colours including green, yellow, orange, pink, and red. They are also known for their excellent resistance to heat, chemicals, and weathering, making them suitable for use in harsh environmental conditions.

Fluorescent pigments find extensive use in a variety of applications such as inks, coatings, plastics, textiles, and paints. They are also used in security printing, safety signs, and high-visibility clothing. Additionally, these fluorescent colours are used in the entertainment industry for creating special effects and in the automotive industry for colouring various automotive components.

Megha International is a leading fluorescent pigments manufacturers in India, the company has a strong presence in the global market and serves customers in over several countries worldwide. Megha International’s fluorescent pigments are known for their excellent quality, brightness, and durability, and are widely used in the printing, plastics, and coatings industries. The company is committed to innovation and product development and offers customized solutions to meet the specific needs of its customers. With a focus on sustainability, Megha International has implemented eco-friendly manufacturing processes and is actively involved in various environmental initiatives. For more information, click on Fluorescent pigments pdf.

Are you looking for Fluorescent Pigments? Transform your materials into vibrant masterpieces!

Buy High quality Fluorescent Pigments at Best Price - Megha International

How Are Fluorescent Dyes Made?

The manufacturing process for fluorescent pigments involves several steps. The first step is to select the appropriate base material, which is typically a white pigment or filler. The base material is then mixed with a fluorescent dye or pigment in a solvent. The mixture is thoroughly blended to ensure that the dye or pigment is evenly dispersed throughout the base material.

Next, the solvent is evaporated from the mixture using a drying process. The drying process may involve heating the mixture or passing it through a series of rollers to remove the solvent. Once the solvent has been removed, the resulting dry powder is collected and then milled to achieve the desired particle size.

The final step in the manufacturing process is to test the fluorescent pigment for quality and performance. The pigment is tested for colour strength, light fastness, heat resistance, and other properties to ensure that it meets the required specifications. If the pigment passes the quality tests, it is packaged and shipped to customers.

It is worth noting that the manufacturing process for fluorescent pigments may vary depending on the specific application and requirements. For example, the process for manufacturing fluorescent pigments for textile applications may involve additional steps such as dyeing and finishing. Additionally, some fluorescent pigments manufacturers use different methods or equipment to produce fluorescent pigments.

Types of Fluorescent Pigments

There are various types of fluorescent pigments available in the market, each with its own unique properties and applications. Some of the commonly used types of fluorescent pigments are:

These pigments are designed to fluoresce under daylight or natural light conditions. They are used in high-visibility applications such as safety signs, traffic cones, and emergency exit signs.

These pigments are designed to fluoresce under ultraviolet (UV) light conditions. They are commonly used in nightclub and party decorations, as well as in printing and security applications.

These pigments change colour with temperature changes and also exhibit fluorescence under UV light. They are used in a variety of applications such as temperature-sensitive packaging, clothing, and toys.

These pigments are soluble in organic solvents and are commonly used in the printing and coatings industries. They are known for their high colour strength and good light fastness properties.

These pigments are water-soluble and are commonly used in the textile industry for dyeing fabrics. They are also used in various other applications such as inks, paints, and coatings.

These pigments are specially designed for use in polyester resins and are commonly used in the production of fiberglass reinforced plastics (FRP) products.

Overall, the choice of fluorescent pigment will depend on the specific application and the desired properties required.

Fluorescent Pigments Properties / Characteristics - Pigment Manufacturer in India

Fluorescent pigments have several properties that make them unique and highly desirable in various industrial applications. Some of the key properties of fluorescent pigments are:

- Fluorescence: Fluorescent pigments are capable of emitting light when exposed to UV radiation, which gives them their vibrant and intense colour. This fluorescence property makes them highly visible even in low-light conditions.

- High Colour Strength: Fluorescent pigments have a high colour strength, which means that they produce strong, bright colours even at low concentrations.

- Good Light Fastness: Fluorescent pigments are known for their excellent light fastness, which means that they can maintain their colour intensity and brightness even after prolonged exposure to sunlight.

- Chemical Resistance: Fluorescent pigments are resistant to many chemicals, making them suitable for use in harsh environments.

- Heat Resistance: Fluorescent pigments can withstand high temperatures without losing their colour intensity, making them suitable for use in high-temperature applications.

- Weather Resistance: Fluorescent pigments are resistant to weathering and can maintain their colour intensity even in harsh outdoor environments.

- Compatibility: Fluorescent pigments are compatible with a wide range of materials, including plastics, coatings, inks, and textiles, making them suitable for use in various applications.

Overall, the properties of fluorescent pigments make them ideal for use in a variety of industrial applications where high visibility, durability, and colour strength are essential.

Advantages of Fluorescent Pigment

There are several advantages to using fluorescent pigments in various applications. Some of the key advantages offered by fluorescent pigment manufacturers are:

- High Visibility: Fluorescent pigments are highly visible even in low-light conditions, making them ideal for use in applications where visibility is critical, such as safety signs, emergency exit signs, and traffic cones.

- Intense Colour: Fluorescent pigments have a high colour strength, which means that they produce vibrant and intense colours even at low concentrations.

- Durability: Fluorescent pigments are known for their excellent light fastness, chemical resistance, heat resistance, and weather resistance properties, which makes them suitable for use in harsh environments.

- Versatility: Fluorescent pigments are compatible with a wide range of materials, including plastics, coatings, inks, and textiles, making them suitable for use in various applications.

- Cost-Effective: Fluorescent pigments are cost-effective compared to other types of pigments, making them an attractive option for many applications.

- Eco-Friendly: Fluorescent pigments are non-toxic and environmentally friendly, making them a safe and sustainable option for use in various applications.

Overall, the advantages of fluorescent pigments make them an ideal choice for use in a variety of applications, including safety signs, textiles, printing, and coatings, where high visibility, durability, and intense colours are required.

Fluorescent Pigments Uses

Fluorescent pigments have a wide range of applications in various industries due to their unique properties. Some of the common applications of fluorescent pigments are:

- Safety Signs and Markings: Fluorescent pigments are used in safety signs and markings to enhance visibility and increase safety in low-light conditions. They are commonly used in traffic cones, barricades, and emergency exit signs.

- Printing: Fluorescent pigments are used in printing applications to produce vibrant and intense colours in magazines, books, and other printed materials. They are also used in the packaging industry to create eye-catching designs on food, beverage, and consumer goods packaging.

- Textiles: Fluorescent pigments are used in the textile industry to produce brightly coloured and high-visibility fabrics, such as safety vests, athletic wear, and swimwear.

- Coatings: Fluorescent pigments are used in coatings to provide high-visibility and enhance safety in industrial environments, such as construction sites, factories, and warehouses. They are also used in the automotive industry to produce custom colours and effects on vehicles.

- Security Printing: Fluorescent pigments are used in security printing applications, such as banknotes, passports, and ID cards, to prevent counterfeiting and enhance security features.

- Party Decorations: Fluorescent pigments are used in party decorations, such as balloons, streamers, and glow sticks, to produce bright and vibrant colours under UV light conditions.

Overall, the applications of fluorescent pigments are vast and varied, making them an essential component in many industries where high-visibility, vibrant colours, and durability are required.

About Megha International

Looking for a Fluorescent Pigments Exporter for brazil?

Megha International (ISO 9001: 2008) Established in the year 1995, at Mumbai, India is the leading fluorescent pigment manufacturers in India that offers an extensive range of Fluorescent Pigments and completive pigment colour price in national as well as international Fluorescent pigments market. Our research and development team carries out constant studies to develop products that reliably set us apart from our competitors and serve our clienteles best. With a remarkable focus on innovation and leveraging new-age expertise, we endeavour to sustain and develop a leading organization on a global scale. The company is among the top 10 pigment manufacturers in world, and is striving to deliver the finest quality of products to the consumers, while being

Market Area of Megha International

As a prominent Fluorescent Pigments supplier, Megha International is proud to export Fluorescent Pigments in a wide range of countries across the globe. Our reach extends to many countries in Asia, including China, Vietnam, Singapore, Thailand, Malaysia, Korea, Philippines, Japan, and Indonesia.

We also serve clients in the Middle East, such as UAE, Saudi Arabia, Kuwait, Qatar, Iraq, and Iran.

In North Africa, we have clients in Algeria, Morocco, and Tunisia, while in Europe, we offer our services to Russia, the UK, France, Italy, Germany, the Netherlands, Romania, and Poland.

In South America, we serve clients in Brazil, Argentina, Colombia, Peru, and Guatemala, as well as in Central America, including Mexico, Costa Rica, and Honduras.

Finally, we also provide our services to clients in the United States and Chile. No matter where our clients are located, we are committed to delivering high-quality dyes and exceptional customer service.

Frequently Asked Question about Vat Dyes

A: Fluorescent pigments are colored pigments that exhibit fluorescence when exposed to UV light, producing a bright and vibrant color.

A: Fluorescent pigments are made by combining a fluorescent dye with a carrier material, such as a resin or polymer.

A: Fluorescent pigments have properties such as high visibility, intense color, good light fastness, chemical resistance, heat resistance, and weather resistance.

A: Fluorescent pigments have applications in safety signs, printing, textiles, coatings, security printing, and party decorations.

A: Fluorescent pigments are generally safe to use and are non-toxic. However, some fluorescent pigments may contain hazardous materials, and it is important to follow proper safety precautions when handling them.

A: Yes, fluorescent pigments can be mixed with other pigments to create custom colors and effects.

A: Fluorescent pigments have good light fastness and can maintain their color intensity even after prolonged exposure to sunlight.

A: Yes, fluorescent pigments are suitable for outdoor use and have weather-resistant properties that make them ideal for harsh outdoor environments.

A: Yes, fluorescent pigments can be used in food packaging. However, it is important to ensure that the pigments are food-grade and safe for use in contact with food.

A: Fluorescent pigments are generally more expensive than other pigments due to the additional cost of the fluorescent dye and the carrier material used in their production. However, they are still a cost-effective option for many applications due to their high color strength and durability.